How to covert waste tyres to fuel oil ?

Scrap tires are common waste products in many 4S auto repair shops. How should this problem be solved?

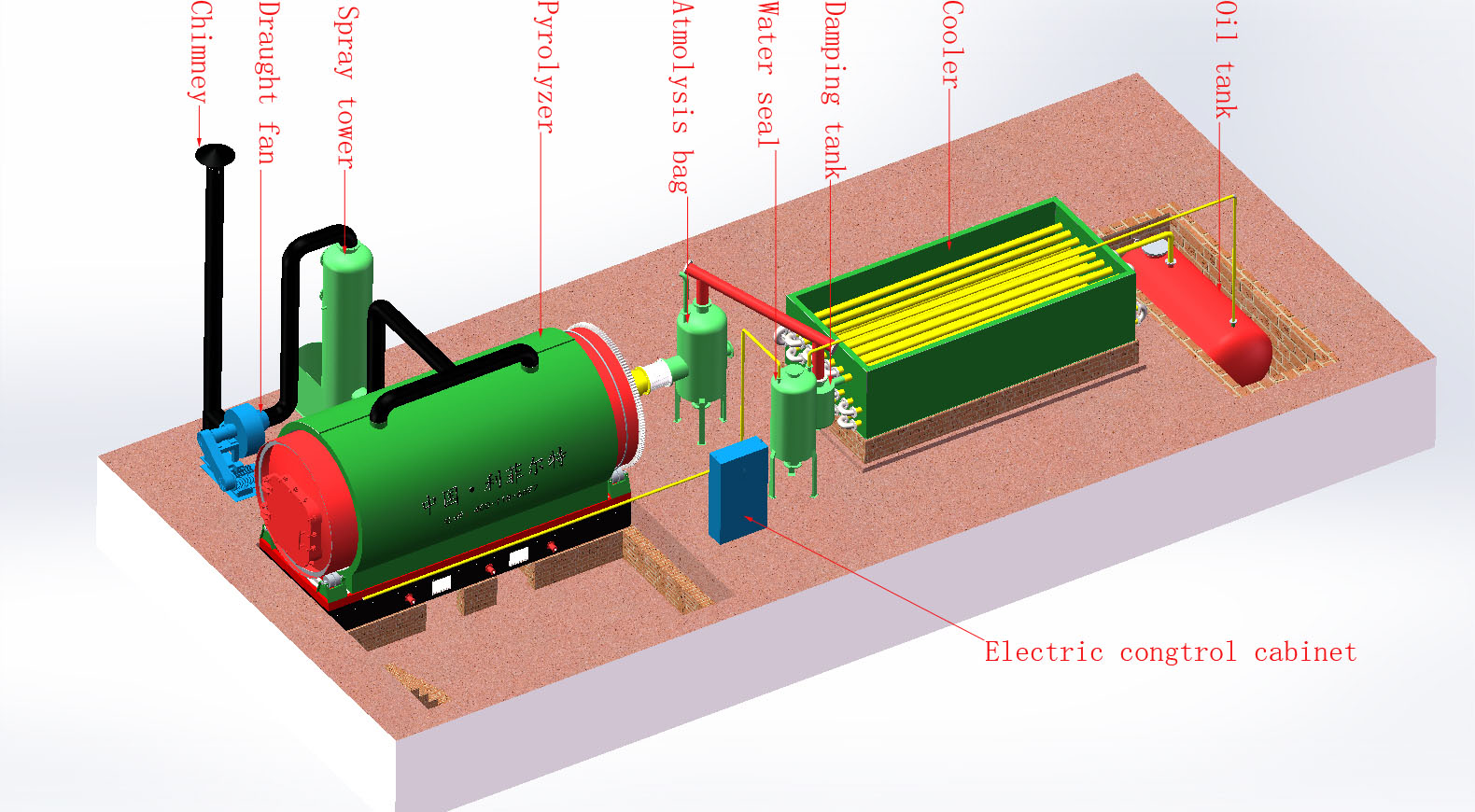

The waste tire pyrolysis equipment converts the waste tire into fuel oil, carbon black, steel wire and combustible gas according to the principle of high temperature pyrolysis. The waste tire is sold to the tire pyrolysis plant which has tyre pyrolysis equipment, and the black pollution is fully treated.

The main workflow of waste tire pyrolysis plant.

1. The waste tires are fed into the reactor via an automatic feeder.

2. The reactor is heated. When the temperature reaches a certain level, the waste tire will be pyrolysised into oil and gas. Some of these oils and gas will be liquefied through the condensing system and flow into the tank; the other part of the uncondensed gas will be condensed and liquefied again into heavy oil to flow into the tank or used as a fuel heating reactor.

3. When the reactor temperature is cooled to below 100 degrees, discharge the carbon black from the reactor.

What are the benefits of running our waste tire pyrolysis for operation within 24 hours?After being accurately measured by engineers, the operation of our pyrolysis plant can earn nearly 2,000 dollars a day in China.

These profits are mainly due to fuel oil , carbon black, and steel wires . The specific uses of these materials are as follows:

1. Fuel oil: Mainly used in iron and steel plants, boiler heating, heavy oil generators, and cement plants.

2. Carbon black: It is mainly used for pressure ball combustion and refined milling. Refined flour can be used for new tires, rubber soles, and pigments.

3. Steel wire: mainly used for waste recycling and recasting.

Mobile/Wechat/Whatsapp:+86-13523737997

Mobile/Wechat/Whatsapp:+86-13523737997

Email:recycling@lefilter.com

Email:recycling@lefilter.com