What are the products of pyrolysis from waste tire ?

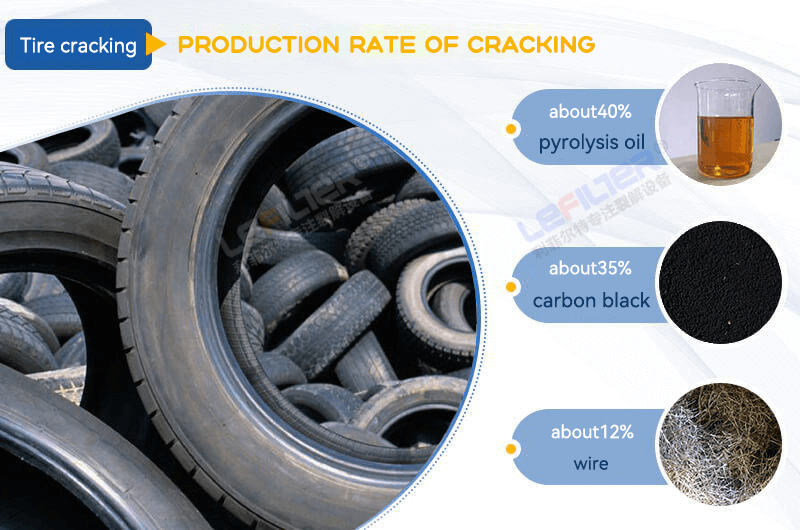

The tire is made of rubber or polyester material through synthetic fiber and high-strength connection. Rubber is the most important component in tires, accounting for 48% of the total tire mass. In addition, 22% (mass percentage, the same below) of carbon black, 15% of metals, 8% of additives, 5% of fabrics, 1% of zinc oxide, and 1% of sulfur.The thermal cracking technology of waste tires refers to the pyrolysis of rubber macromolecules at a suitable temperature (generally 400~800 °C) in an oxygen deficient or inert gas atmosphere to obtain pyrolysis gas, pyrolysis oil and pyrolysis carbon black. After the whole tire or broken tire is sent to the cracking furnace of waste tire refining equipment, the volatile is thermally resolved and condensed to obtain liquid products. The non condensable gaseous products can be burned to provide heat source for the cracking furnace.

Of course, the products of tire pyrolysis are all primary products. The pyrolysis gas is H2 and some C1-C4 hydrocarbons. Its calorific value is equivalent to that of natural gas. It is generally used for heating in the tire pyrolysis furnace, and the surplus can be stored; Pyrolysis oil has complex components, multiple fractions, high sulfur and nitrogen compounds, which can’t directly replace gasoline and diesel oil. It is generally used as fuel oil for industrial boilers. After hydrogenation or distillation, gasoline and diesel oil that is close to the international standard can be obtained, and chemical basic raw materials such as benzene, toluene, xylene, limonene can also be further processed and extracted; Pyrolysis carbon black ash is high in composition and needs further treatment to replace commercial carbon black.

Mobile/Wechat/Whatsapp:+86-13523737997

Mobile/Wechat/Whatsapp:+86-13523737997

Email:recycling@lefilter.com

Email:recycling@lefilter.com