Under what conditions can the oil sludge pyrolysis plant achieve the best pyrolysis of oil sludge

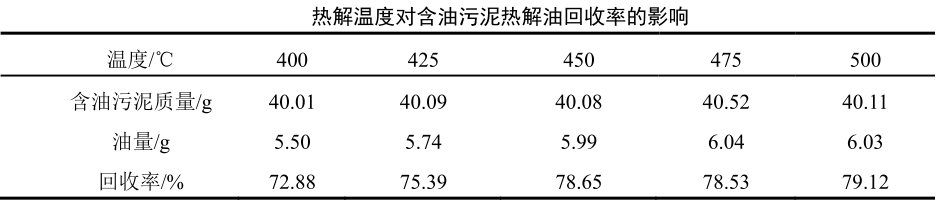

When the heating rate is setting at 10 ℃/min, we will heat decompose the sludge in the oil sludge refining equipment pyrolysis furnace for 4h, and see the impact of 400-500 ℃ on pyrolysis process. See the following figure for the laboratory analysis results of Lefilter Shangqiu Branch.

It can be seen from the results in the above figure that when the pyrolysis temperature rises in a gradient, the recovery rate of the oil generated by oil sludge pyrolysis also rises in a gradient. When the temperature of oil sludge pyrolysis reaches 450 ℃, the oil recovery effect is obviously slow and tends to be balanced. Although the recovery rate increases, the degree of increase is low. This is because the sludge can not be fully cracked and condensed at a lower temperature in the early stage. However, with the increase of pyrolysis temperature, the macromolecular organic matter in the sludge is decomposed into small molecular substances, and the thermal cracking degree of the sludge is significantly increased, which increases the oil production rate. However, with the increasing of pyrolysis temperature, the amount of gas generated by pyrolysis increases, while the recovery of pyrolysis oil tends to be stable and decreases. Therefore, 450 ℃ is selected as the optimal pyrolysis temperature, and 78.65% of the oil in the sludge can be recovered at 450 ℃.

Loading and delivery of Vietnam LES-2675 oil sludge refining equipment

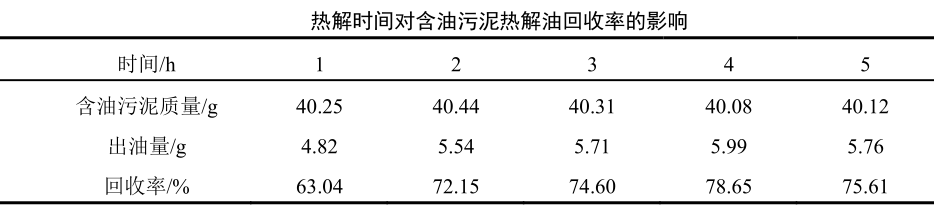

The pyrolysis temperature is 450 ℃, we discuss the influence of analysis time on sludge pyrolysis process when the heating rate is 10 ℃/min. Seeing the following figure for laboratory results of Lefilter Shangqiu Branch.

It can be seen from the above figure that when the pyrolysis time increases in a gradient manner, the recovery rate of oil generated from oil sludge pyrolysis process increases first and then decreases; When the pyrolysis time is 1~4h, the amount of recovered oil increases continuously with the extension of time, and the highest recovery rate of pyrolysis oil is 78.65% at about 4h; When the pyrolysis time continued to increase, the recovery of pyrolysis oil showed a downward trend. This phenomenon is mainly due to the fact that when the pyrolysis time is short, the organic hydrocarbons in the sludge cannot be separated completely, and some refractory substances in the oil sludge are still decomposed. When the pyrolysis time is too long, the separated crude oil will be cracked and condensed again in the reactor, and some liquid products will be transformed, resulting in low recovery rate of liquid products. Therefore, considering the influence of time on oil recovery, the pyrolysis reaction time is 4h.

Cambodia Stainless Steel Oil Sludge Refining Project

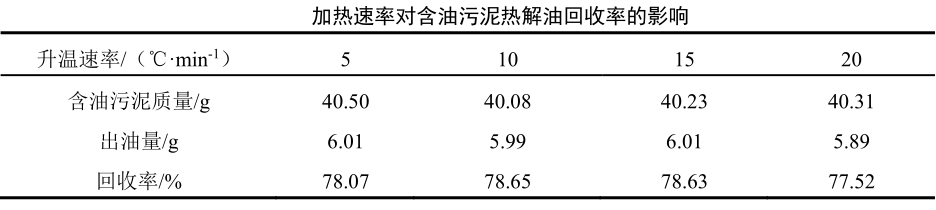

Pyrolysis at 450 ℃ for 4h, and the effect of different heating rates on oil recovery in sludge.The laboratory results of Lefilter Shangqiu Branch are shown in the following figure:

It can be seen from the results in the above figure that during the pyrolysis process, when the heating rate is within the range of 5-10 ℃/min. the oil recovery effect in the sludge is good and increases in gradient; At the heating rate of 10℃/min , 78.65% of the crude oil in the sludge can be recovered. If the heating rate is higher, the oil recovery rate is significantly reduced. This is because the heating rate is low and the temperature in the pyrolysis furnace is low at the beginning, which increases the pyrolysis time of the sludge at low temperature. Some organic matters in the sludge cannot be completely decomposed, and the oil recovery rate is relatively low; When the heating rate is high, the oil sludge will soon be heated to a higher temperature, so that the oil-water substances in it will be heated to boiling, which will cause some of the oil sludge splashed on the reactor to be unable to be fully heated, and finally lead to a smaller recovery rate. Therefore, in order to recover the maximum proportion of crude oil, the heating rate of 10℃/min is used to raise the temperature.

Through the above screening of experimental conditions, it can be seen that the optimal conditions for oil sludge pyrolysis are: the oil sludge is heated to 450 ℃ at a rate of 10 ℃/min, and it is pyrolyzed in the oil sludge refining equipment for 4h.

Lefilter always adheres to the core value of "creating value for customers and being an expert in cracking and refining equipment", and insists on putting customers first to ensure timely and quick response to customer needs. The professional marketing team and technical team provide users with pre-sales, in sales and after-sales services 7 * 24 hours, including technical consultation, equipment selection, installation and commissioning, equipment customization services and integrated application solutions.

Mobile/Wechat/Whatsapp:+86-13523737997

Mobile/Wechat/Whatsapp:+86-13523737997

Email:recycling@lefilter.com

Email:recycling@lefilter.com