How to Start/stop the waste tire pyrolysis plant

(1) Driving operation procedure for tyre pyrolysis plant.

① Check whether the main reaction equipment and its auxiliary equipment, instruments, etc. are normal, and whether all valves are in the specified state;

② Open the feeding bin again, open the feeding valve to add raw materials, etc. After feeding, close the feeding valve;

③ Input fuel, such as using hot gas or pyrolysis gas for energy supply;

④ Connect the power supply and adjust the reaction parameters to the appropriate working condition to start the reaction; Simultaneously activate the circulating water, cooling water, etc. of the reaction equipment, and activate the waste gas disposal facilities;

⑤ Observe the working condition of each instrument at any time. If it does not meet the requirements, it should be adjusted immediately if it belongs to this post, and it should be notified immediately if it belongs to other posts.

⑥ After pyrolysis, the material is discharged and coarse carbon black, steel wire, and fuel oil are collected. According to the above operation, the coarse carbon black is fully sealed and packaged. The non condensable gas generated during the start-up phase is desulfurized by a "two-stage alkali washing tower+alkali water seal" and then enters the pyrolysis furnace for combustion and heating. The generated flue gas is then treated by a water film dust removal tower for dust removal before reaching the standard discharge.

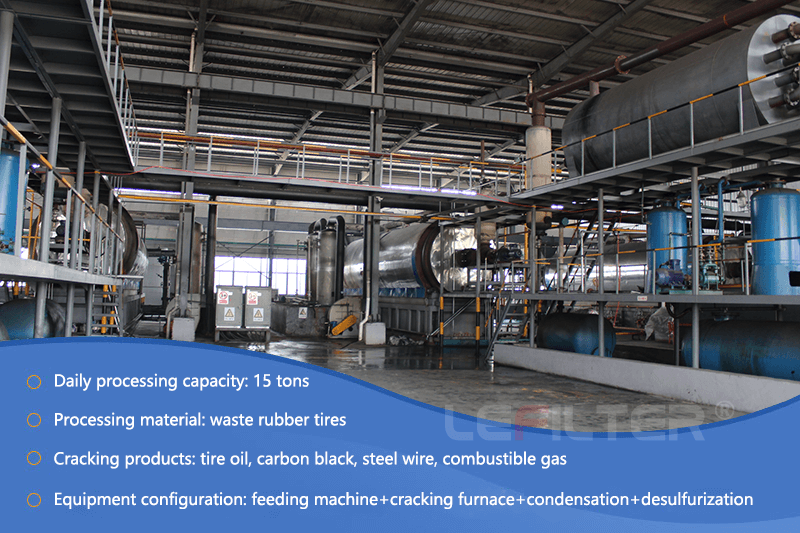

Waste tire pyrolysis plant

Waste tire pyrolysis plant

(2) Parking operation procedure for tyre pyrolysis plant.

① Complete the reaction of each batch of materials and prepare for shutdown;

② The finished product after reaction is discharged into the product container or sealed for packaging;

③ Close the discharge valve;

④ Stop circulating water, cooling water, etc. of the reaction equipment;

⑤ Stop the exhaust gas treatment device in the workshop. According to the above parking procedure, the production of cracking gas gradually stops. During the parking phase, the non condensable gas still enters the pyrolysis furnace or combustion chamber for combustion after being desulfurized by the "two-stage alkali washing tower+alkali water seal". The generated flue gas is then removed by the water film dust removal tower before reaching the standard discharge.

Mobile/Wechat/Whatsapp:+86-13523737997

Mobile/Wechat/Whatsapp:+86-13523737997

Email:recycling@lefilter.com

Email:recycling@lefilter.com