Working process for semi-continuous pyrolysis plant

Working process for semi-continuous pyrolysis plant

Rubber powder pyrolysis plant process

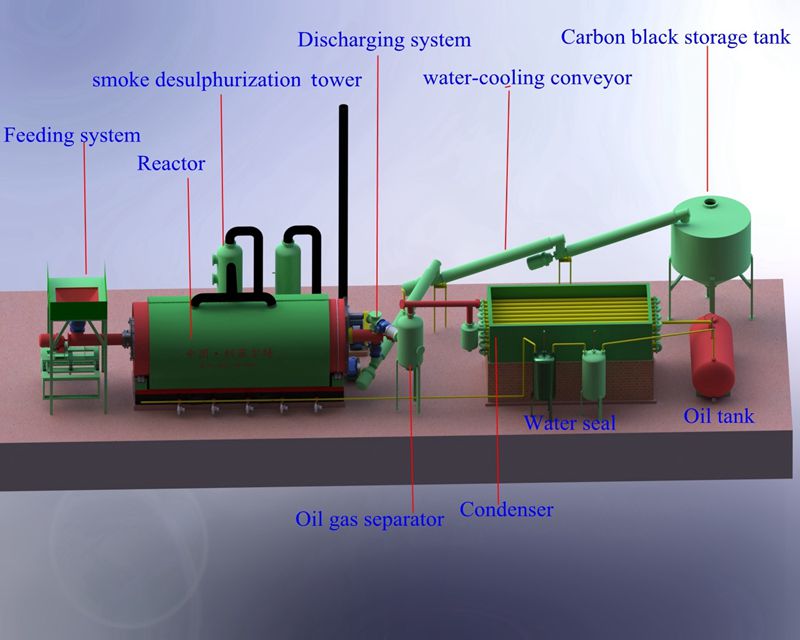

LEFEIERTE rubber powder pyrolysis plant including powder feeding systems ,carbon black discharging systems, carbon black collecting systems, condenser systems, waste gas purifying

systems etc.Comparing to batch type pyrolysis plant, it have much efficiency and can get higher oil yield ,increase production efficiency. It can discharge carbon black in 200℃。

Powder feeding system

Carbon black discharge system

Carbon black collection system

A. Technology features:

1. Lifeierte rubber powder pyrolysis plant , equipped with

super-powerful feeding conveyor and carbon black discharge

conveyor, to shorten the time of feeding and discharge;

2. High temperature ball valve at the inlet and slag outlet to

ensure a good sealing effect;Xinxiang Lifeierte Filter Co.,ltd Shangqiu Branch

Email:recycling@lefilter.com Cellphone:0086-13523737997

3. Cooler to ensure the maximum cooling of oil and gas into oil,

and the oil powder output rate is about 50%.

B. Production process and working hours

1.Feeding:Powder feed for 1 hours and can feed 9-11 tons to the

reactor 2.8x7.5m .

2.Pyrolysis process:8-9 hours

3.Discharging :Discharge at arround 200 centigrade,through 3

water-cooling conveyor to carbon black storage tank .This

process for 2 hours.

4.After discharging, keep feeding and continue for the next circle.

One whole production process lasts for 14-16 hours and can

produce pyrolysis oil 3 circles in 2 days.

C. Difference with Batch type pyrolysis plant

1. Powder feeding screw conveyor .

2. Discharge carbon black in the oil gas outlet by screw conveyor.

Then carbon black moved to 3 connected water-cooling conveyor to carbon black storage tank.

3D drawing design

Mobile/Wechat/Whatsapp:+86-13523737997

Mobile/Wechat/Whatsapp:+86-13523737997

Email:recycling@lefilter.com

Email:recycling@lefilter.com