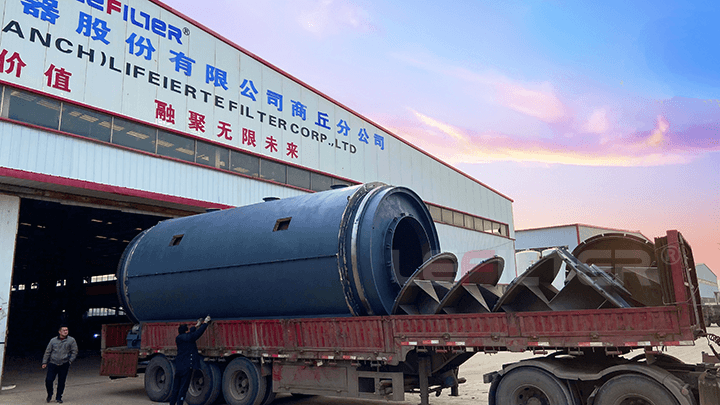

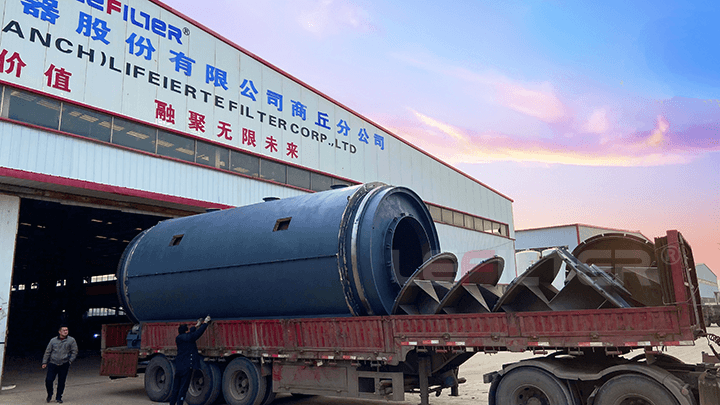

Auto repair shops are usually discarded and sold waste tires at low prices. Waste tires can now be processed and equipment that turns waste into treasure has emerged. The recycling waste tire to oil plant utilizes the principle of pyrolysis to crack the waste tire into a chemical process of fuel oil, carbon black, steel wire, and combustible gas in a closed environment.

The main workflow of waste tire processing equipment:

First of all, before operating the recycling waste tyre to oil plant , it is necessary to prepare enough waste, mainly bicycle tires, motorcycle tires, car tires, truck tires and other heavy machinery tires. Of course, in addition to various types of tires, various waste plastics, waste rubber, and other organic solids can be used as raw materials.

Next, the reactor is heated and the prepared waste is sent to the reactor via an automatic pusher. High temperature pyrolysis into oil gas.

Again, these oils gases pass through the cooling system, are liquefied as flammable oil after being cooled, are filtered by oil-gas separators, and fall into oil tanks.

Finally, non-condensable gas is also called flammable gas. It has good flammability. This gas will be reused in the heating raw material of the reactor., but also improves the efficiency of equipment operation. The carbon black produced during the operation of the equipment is automatically discharged from the furnace through side slag discharge.

For example10 tons of recycling waste tyre to oil plant , the following benefits can be obtained in one day when operating the equipment.

These benefits mainly come from the end product of recycling waste tyre to oil plant :

1. 40%-45% fuel oil: 4.5T, calculated at $400 per ton, 4.5T X 400USD=1800USD

2. 30% carbon black: 3T

Carbon black can have two uses:

A. Direct sales: 80 US dollars per ton, 3T X 80USD = 240USD

B. Refined milling: Calculated at US$320 per ton, 3T X 320USD=960 USD

3. 15% steel wire: 1.5T, calculated at $128 per ton, 1.5T X 128USD=192USD

These net benefits, minus the cost of buying scrap tires, as well as a small amount of water consumption and worker costs, can get nearly 2,000 US dollars a day.

The profits of these materials are so huge. What are their specific uses?

1. Fuel oil: It is mainly used for the combustion oil in steel plants, cement factories and bath centers, and can also be used for power generation of heavy machinery.

2. Carbon black: It is mainly used for pressure ball combustion and refined milling. Refined flour can be used for new tires, shoe soles, and pigments.

3. Steel wire: mainly used for waste recycling and recasting.