Lefilter waste tire recycling equipment uses thermal decomposition technology to decompose macromolecules into smaller molecules when high temperature.

At present, the pyrolysis plant is divided into three types: batch type, semi-continuous, and continuous type.

It is 100% recycling equipment, not only a profitable business, but also helpful for improving the local environment, avoid garbage pollution.

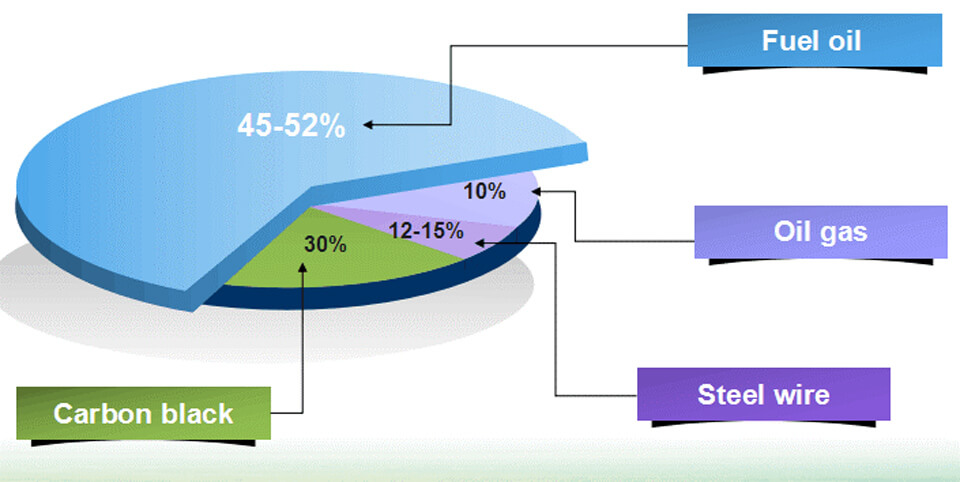

For 1T waste tire,it can produce final products which have different valuable application as below:

Final products Yield and uses:

| Final Products | Yield | Application |

| Fuel Oil | 45%-55% |

1. Heating material:sell to cement factory, glass factory, ceramic factory, electric power factory, steel making factory, boiler factory, etc. 2. Used for heavy oil generator for electricity generation. 3. Deep process it into diesel oil then can be used in cars,trucks, tractors, etc. |

| Carbon Black | 30%-35% |

1. Make it into pellet or briquette as heating material. 2. Make it into N220, N330, N550 or N660 which is widely used in tire making industry. 3. Make it into plastic grains then sold to plastic industry. |

| Steel Wire | 12%-15% |

1. Sell it to iron and steel factory directly. 2. Sell it to steel distributors. |

| Flammable Gas | 8%-10% |

1. Recycled into furnace to heat reactor instead of coal/wood/oil/natural gas. 2. Store it then supply the pyrolysis equipment heating,it’s recycling. |

Pyrolysis plant’s technical parameters:

| Items | Contents | ||||||

| Input-Raw Materials | Waste tire/rubber/plastic/Medical waste/MSW/Oil sludge/Aluminum plastic | ||||||

| Final products | Fuel oil, carbon black, steel wire, flammable gas | ||||||

| P/N | LES-2266 | LES-2666 | LES-2675 | LES-2880 | |||

| Capacity/24h | 6Ton/Batch | 10Ton/Batch | 12Ton/Batch | 15Ton/Batch | |||

| Oil production(T)/24h | 2.7-3.2 | 3.6-4 | 4.5-5 | 5.4-5.8 | |||

| Power | 5.5KW | 5.5KW | 7.5KW | 7.5KW | |||

| Cooling water(T/h) | 4 | 5 | 6 | 8 | |||

| Rotate speed(r/min) | 0.4 | ||||||

| Heating type | Direct heat | ||||||

| Cooling type | Water-cooled | ||||||

| Noise(dB) | ≦85 | ||||||

| Operating | Intermittent | ||||||

| Driving mode | Internal gear | External gear | |||||

| Reactor material | Q345R/Q245R/310S+Boiler plate/Stainless steel | ||||||

| Structure | Horizontal rotation | ||||||

| Host weight(T) | 20 | 23 | 26 | 28 | |||

| Reactor size(mm) | Ø2200*6600 | Ø2600*6600 | Ø2600*7500 | Ø2800*8000 | |||

| Space needed | 200-300 square meters (Width:10m, Length:20m-30m) | ||||||

| Combustion value | 35-50m3 | ||||||

| Note |

We supply customized plant,we need some basic information: What kind of raw material to recycle? Tires for car, truck, motorbike... Plastic of PVC,PE, PP,PS,ABS,bags,acrylic, rubber, medical waste, oil sludge industrial waste material... What capacity do you need to recycle per day? (Ton) What fuel do you use? Coal,gas,wood... | ||||||

Available fuels and specific data for pyrolysis:

| No. | Item | Consumption |

| 1 | Coal(for choice) | 500kg/day |

| 2 | Wood(for choice) | 500kg/day |

| 3 | Natural gas(for choice) | 400㎥ |

| 4 | Oil(for choice) | 300-350kg/day |

| 5 | Electricity | 200kwh/day |

| 6 | Water(recycled) | 60㎥ /month |

| 7 | Total power | 20kw |

| 8 | Land area | 30m*10m |

Comparison of different Operations:

| No | Operation | Description |

| 1 | Batch |

♦ Capacity 5T-15T per day , Low investment cost ,Can be loaded with whole tires , no need for shredding. ♦ Auto screw carbon discharging , no dust flying , high efficiency. ♦ Modular design condenser , more convenient for installation and transportation , Furnace door (shape and size) can be designed based on client requirement. ♦ Special emission purification system. |

| 2 | Semi-continuous |

♦ Capacity 15-16T per day, Auto feeding system. Materials needs to be shredded smaller than 50mm. ♦ Loading under high-temperature, no need to wait for reactor cooling. Fully enclosed production system. ♦ Auto screw carbon discharging , no dust flying , high efficiency. ♦ Special emission purification system. |

| 3 | Continuous |

♦ Capacity 20-25T tires per day , materials needs to be smaller than 20mm. Auto feeding and auto carbon discharging 24 hour per day. ♦ Whole equipment adopt modular design, assembled in fabrication factory, greatly shorten installation period. ♦ No need for foundation, easy to be transported to another project. ♦ Fully enclosed production, special sealing system to guarantee safety of operation ,no bad smell generated ,no dust flying. ♦ Special emission purification system. |

Xinxiang Lefilter Filter Corp.,ltd Shangqiu Branch is a collection research and development,production,sales and after-sales service in one of the specialized,intergrated company. We're specialized in producing waste tyres pyrolysis machine, waste plastic pyrolysis plant,waste rubber pyrolysis equipment, oil sluge pyrolysis machine, Waste tyre Oil/plastic oil,waste motor oil distillation plant,and Municipal Solid Waste Sorting Machine.All of the machines aims to manage waste and recycle them to energy or other resource,which meet our mission.We have first-class sales team,professinal technical team,efficient production systems and have a perfect customer service system.As a promising Manufacturer, Supplier and Exporter of Waste Tyre Pyrolysis Plant, we are engaged in delivering only best quality and high performance rendering products, that are especially designed to cater different needs and require.

Following is our company Strength for reference:

1.10 Year's production experience.

2.24 hours online service.

3.Engineer Overseas Service Provided.

4.Production capacity 25 sets/ month,300 sets anually.

5.Exported and Installed in India,USA,Brazil,Russia,Turkey,Egypt,Nigeria,Thailand,Indonesia,Australia,England etc.

♦Provide technical guidance and supporting equipment and materials;

♦ Answer customers' questions, assist customers or design laser processing scheme for customers from the technical point of view;

♦ Provide equipment exhibition hall for customers to visit, proofing and test machine.

♦ Assist customers to plan and design the water and electricity equipment of the production site;

♦ To provide customers with a full set of operating instructions;

♦ Provide free training to the customer's equipment operators.

♦1 Years warranty for whole set machine;

♦ During the warranty period, the company will also send technicians to the site from time to time to carry out technical patrol and answer the questions raised by customers.

Our advantages:

Outstanding Features:

1. High Efficiency:

♦Automatic feeding system, automatic dust-free discharging system.

♦Producing with special structure, Fully automatic Submerged arc welding technology.

♦ Well-designed condensing system for more complete cooling, higher oil yield and better oil quality.

2. Security:

♦ Adopting automatic submerged-arc welding technology

♦ All of the welding will be detected by the ultrasonic nondestructive testing method to ensure the welding quality and the welding shape.

♦ Equipped with anti-explosion device, safety valves, emergency valves, pressure and temperature meters, as well as the alarming system.

♦ Adopting manufacture process controlling system on the quality, every manufacture process, manufacture date, etc.

3. Environmental-friendly:

♦The dust removal process enables the exhaust gas dust emission to reach the GB13271-2001 boiler air pollutant discharge standard, and the environmental protection special supply;

♦ Emission Standard: Adopting special gas scrubbers to remove acid gas and dust from smoke.

♦ Smell during operation: Fully enclosed during the operation

♦Water pollution: No pollution at all.

♦ Solid pollution: the solid after pyrolysis is the crude carbon black and steel wires which can be deep-processed or sold directly with its value.

Packaging & Shipping:

Pyrolysis plants,one 40'FR is for the reactor,and the other 40'FR for the horizontal cooling condenser, 40'HQ containers is to load oil tank,dedust device and other spare parts.The reacor is about 7500m *3200mm*3200mm. It is doable to take 40FR. It is over width and over height. The horizontal cooling condenser is 6000mm*3000mm*1800mm,have good performance for cooling oil gas .It's proper for using 40'FR.We also can design vertical cooling condensor for you,pack in 40'HQ,it's according to your request.

FAQ

1.What is our Qualification?

We are professional waste tyre and plastic pyrolysis plant manufacturer, with more than 10 years' and 20 years' boiler manufacture experience.

2.What kind of raw material to recycle?

We specialized in manufacturing pyrolysis plant for waste tyre/waste plastic/waste oil slugge, MSW etc

Tires for car, truck, motorbike...

Plastic of PVC,PE, PP,PS,ABS,bags,acrylic, rubber, medical waste, oil sludgeindustrial waste material...

3.How many countries we have exported?

Our product have been successfully exported and Installed in India,USA,Brazil,Russia,Turkey,Egypt,Nigeria,Thailand,Indonesia,Australia,England etc.

4.What is our Warranty Period?

The Warranty Period is ONE YEAR with lifelong service and 24 hours online service.

Quotation&Offer

We supply customized plant,we need some basic information. To choose the waste tire pyrolysis equipment and offer a proper quotation for you ,kindly confirm following questions:

1.Raw material :Waste tyre or plastic ?

2.Production capacity ?(ton/day)

3. What's the burning material ?(Choose wood, coal, oil or natural gas as combustion materials,which one?)

4.What kind of pyrolysis equipment?(Batch or Semi-Continuous Type?)

5.What's your plan for this project ?

6.The final product will be used for?

7.What's the voltage in your country?

8.What's the environmental standard in your country?

9.Other special requirements.

If interested, Call me for detailed pyrolysis plant cost report.