Lefilter waste tire recycling equipment uses thermal decomposition technology to decompose macromolecules into smaller molecules when high temperature.

At present the pyrolysis plant is divided into three types:batch type,semi-continuous,and continuous type.

It is 100% recycling equipment, not only a profitable business, but also helpful for improving the local environment, avoid garbage pollution.

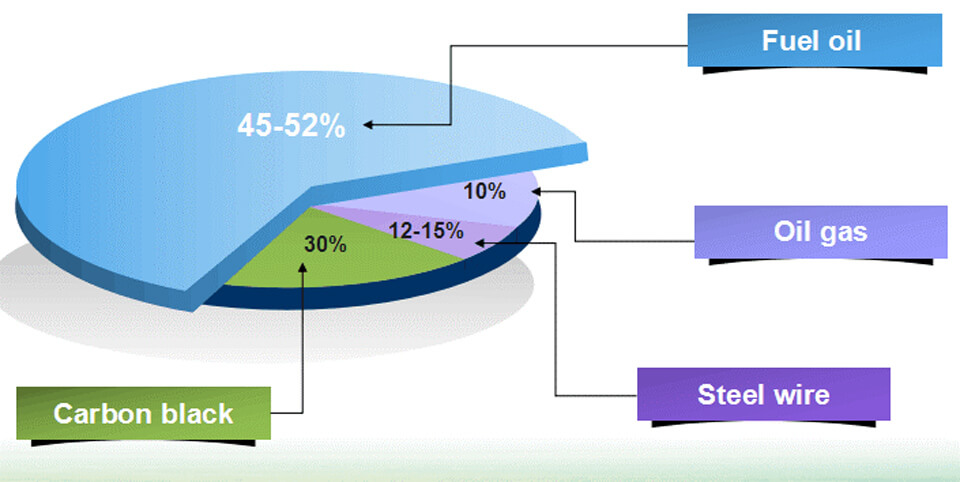

For 1T waste tire,it can produce final products which have different valuable application as below:

Output products Yield and uses

| Final Products | Yield | Application |

| Fuel Oil | 45%-55% | 1. Heating material:sell to cement factory, glass factory, ceramic factory, electric power factory, steel making factory, boiler factory, etc. 2. Used for heavy oil generator for electricity generation. 3. Deep process it into diesel oil then can be used in cars,trucks, tractors, etc. |

| Carbon Black | 30%-35% | 1. Make it into pellet or briquette as heating material. 2. Make it into N220, N330, N550 or N660 which is widely used in tire making industry. 3. Make it into plastic grains then sold to plastic industry. |

| Steel Wire | 12%-15% | 1. Sell it to iron and steel factory directly. 2. Sell it to steel distributors. |

| Flammable Gas | 8%-10% | 1.Recycled into furnace to heat reactor instead of coal/wood/oil/natural gas. 2.Store it then supply the pyrolysis equipment heating,it’s recycling. |

Pyrolysis plant’s technical parameters:

| Items | Contents | ||||||

| Input-RawMaterials | Waste tire/rubber/plastic/Medical waste/municipal solid waste/waste organic glass | ||||||

| Final products | Fuel oil, N220, N330 carbon black, steel wire, flammablegas. | ||||||

| P/N | LES-2266 | LES-2666 | LES-2675 | LES-2880 | |||

| Capacity/24h | 6Ton/Batch | 10Ton/Batch | 12Ton/Batch | 15Ton/Batch | |||

| Oil production(T)/24h | 2.7-3.2 | 3.6-4 | 4.5-5 | 5.4-5.8 | |||

| Power | 5.5KW | 5.5KW | 7.5KW | 7.5KW | |||

| Cooling water(T/h) | 4 | 5 | 6 | 8 | |||

| Rotate speed(r/min) | 0.4 | ||||||

| Heating type | Direct heat | ||||||

| Cooling type | Water-cooled | ||||||

| Noise(dB) | ≦85 | ||||||

| Operating | Intermittent | ||||||

| Driving mode | Internal gear | External gear | |||||

| Reactor material | Q345R/Q245R/310S+Boiler plate/Stainless steel | ||||||

| Structure | Horizontal rotation | ||||||

| Host weight(T) | 20 | 23 | 26 | 28 | |||

| Reactor size(mm) | Ø2200*6600 | Ø2600*6600 | Ø2600*7500 | Ø2800*6600 | |||

| Space needed | 200-300 square meters (Width:10m, Length:20m-30m) | ||||||

| Combustion value | 35-50m3 | ||||||

| Note | We supply customized plant,we need some basic information:What kind of raw material torecycle? Tiresforcar, truck, motorbike... Plasticof PVC,PE, PP,PS,ABS,bags,acrylic,rubber, medical waste, oil sludge industrial waste material...What capacity do you need torecycleper day?(Ton)What fueldo you use? Coal,gas,wood... | ||||||

| No. | Item | Consumption |

| 1 | Coal(forchoice) | 500kg/day |

| 2 | Wood(forchoice) | 500kg/day |

| 3 | Naturalgas(forchoice) | 400㎥ |

| 4 | Oil(forchoice) | 300-350kg/day |

| 5 | Electricity | 200kwh/day |

| 6 | Water(recycled) | 60㎥/month |

| 7 | Totalpower | 20kw |

| 8 | Landarea | 30m*10m |

| No | Operation | Description |

| 1 | Batch | Capacity 5T-15T per day , Low investment cost ,Can be loaded with whole tires , no need for shredding. Auto screw carbon discharging , no dust flying , high efficiency. Modular design condenser , more convenient for installation and transportation , Furnace door (shape andsize) can be designed based on client requirement. Special emission purification system. |

| 2 | Semi-continuous | Capacity 15-16T per day, Auto feeding system. Materials needs to be shredded smaller than 50mm. Loading under high-temperature, no need to wait for reactor cooling. Fully enclosed production system. Auto screw carbon discharging , no dust flying , high efficiency. Special emission purification system. |

| 3 | Fully Continuous | Capacity 20-25T tires per day , materials needs to be smaller than 20mm. Auto feeding and auto carbondischarging 24 hour per day. Whole equipment adopt modular design, assembled in fabrication factory, greatly shorten installation period. No need for foundation, easy to be transported to another project. Fully enclosed production, special sealing system to guarantee safety of operation ,no bad smell generated ,no dust flying. Special emission purification system. |